Understanding OSHA Construction Safety Signs

Construction sites are busy environments filled with machines, tools, and workers performing tasks. Whether you're guiding workers, alerting visitors, or preventing accidents, safety signs are essential to mitigate potential hazards.

In this guide by eSigns, we explain what you need to know about construction safety signs: their meanings and OSHA requirements, worker and supervisor responsibilities, as well as common mistakes to avoid to help keep construction sites safe.

Why Construction Safety Signs Matter

Construction sites are dangerous working environments. Safety signs with visual warnings clearly and effectively communicate hazards. When used properly, they minimize confusion, reinforce training, and help prevent injuries from slippery surfaces, heavy machinery, and overhead work.

Understanding OSHA Regulations and ANSI Standards

The Occupational Safety and Health Administration (OSHA) implements regulations under 29 CFR 1926.200, which covers accident prevention signs and tags. These rules are specifically designed for construction environments, where hazards are often temporary and constantly changing.

Key Requirements

- Signs must be clearly seen and easy to read, even in busy or low-visibility conditions.

- The sign type should match the hazard level. For example, danger signs are for immediate threats, while caution signs indicate potential hazards.

- To avoid confusion or complacency, signs must be removed or covered once the hazard is no longer present.

The Role of ANSI Standards in Construction Safety Signs

While OSHA focuses on workplace safety regulations, the American National Standards Institute (ANSI) provides detailed design standards for colors, symbols, and formats. Both OSHA and ANSI work together to ensure safety signs are consistent, visible, readable, and easy to understand.

Construction vs. General Industry Standards

Construction hazards are temporary and constantly changing as sites evolve, which is why OSHA rules emphasize flexible, responsive signage — unlike general industry standards that address permanent hazards.

Types of OSHA Construction Safety Signs and Their Requirements

Think all safety signs mean the same thing? Here are various types of OSHA construction safety signs and how each one helps workers spot hazards and take action:

Danger Signs

Danger signs inform workers of immediate, life-threatening hazards. These signs feature a red background and the word “DANGER” in bold, white or black lettering. Some examples include high-voltage areas, fall hazards, and crane operating zones. According to OSHA, danger signs should be placed when there’s a direct threat to workers’ safety

Warning Signs

Warning signs alert workers to hazards that can cause serious or death, but not as immediate as danger signs. The color scheme for the word “WARNING” is composed of an orange background with black text, while the message panel has a white background with black text. Warning signs are often used in heavy equipment operation areas, overhead load zones, and temporary structural hazards.

Caution Signs

Caution signs are used to indicate hazards that may cause minor to moderate injuries. They alert workers to proceed carefully and pay attention wherever a sign is placed. These signs have a yellow background with the word “CAUTION” in black lettering, and warn of risks such as wet floors, trip hazards, or low-clearance areas.

Exit Signs

Not all construction signs warn about potential hazards; some work as guides for safe movement. Exit signs are essential on construction sites, as they help workers locate temporary exits and emergency routes during evacuation. OSHA regulations require that exit routes be present in workplaces and that signs be lettered in red or, in some cases, green on a white background.

Safety Instructions

Safety instruction signs remind workers of required actions, such as wearing personal protective equipment (PPE), including hard hats, goggles, gloves, or high-visibility vests. These signs help reinforce PPE regulations and support OSHA training efforts

Directional Signs

Similar to exit signs, directional signs help workers navigate their way to a construction site. These signs use white as the primary background color with a black panel and a white symbol. Some examples of directional signs point to elevators, assembly points, and other areas on the job site.

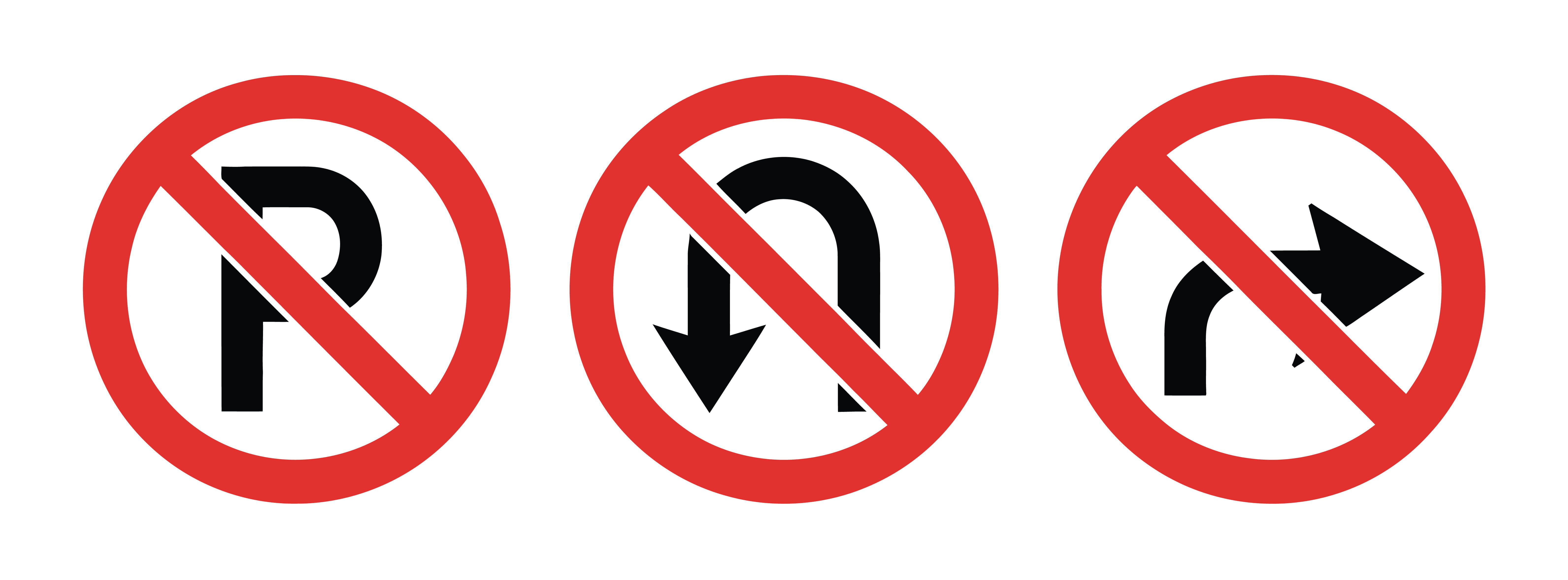

Prohibition Signs

Prohibition signs inform workers and visitors must not do on construction sites. These signs focus on preventing unsafe actions that can lead to various hazards, such as accidents, injuries, or equipment damage. Prohibition signs are often displayed near restricted areas, equipment, and other hazardous activities. Their design features a black icon with a red circle and a diagonal slash. Popular examples include “No Smoking,” No Unauthorized Entry,” and “Do Not Operate.”

Placement Considerations

Because job sites are constantly changing, construction signs must be routinely checked and updated regularly to ensure they remain visible, accurate, and unobstructed.

Traffic Control Signs and Devices in Construction Zones

Traffic management is essential in construction sites that affect roadways or pedestrian traffic. They must follow standards set by the Manual on Uniform Traffic Control Devices (MUTCD) for work zone signs, parking signs, cones, barricades, and channelizing devices.

While OSHA focuses on worker safety, MUTCD standards help protect drivers, pedestrians, and the public. Traffic control signs should comply with OSHA and MUTCD requirements to ensure workers and drivers in and around construction zones remain informed and protected.

Training Requirements for Construction Workers and Supervisors

OSHA construction safety signs are only effective when workers can easily identify and understand their meanings. Here’s why training is critical for signage compliance.

Workers should be trained to:

• Identify various types of construction safety signs

• Understand what actions they must take for each hazard

• Learn the difference between permanent safety signage and temporary job-site signs

Supervisors and Management Responsibilities

Site managers and supervisors are responsible for:

• Choosing the right signs for each hazard

• Displaying them properly in areas where they can be seen

• Monitoring their condition

• Performing hazard assessments and ensuring signs reflect current hazards

• Stay updated about applicable OSHA and MUTCD standards

• Introducing new employees to jobsite safety orientations

• Provide proper traffic control training

Common Construction Signage Mistakes to Avoid

The smallest signage mistakes can cause confusion or accidents on site. Watch out for these common mistakes and avoid them from happening:

• Using homemade or non-compliant signs

• Following outdated OSHA, ANSI, and MUTCD standards

• Placing signs in areas with an obstructed view

• Leaving signs as they are after hazards are removed

• Confusing general industry signs with construction-specific requirements

Clear, compliant, and visible safety signs, along with proper training, help identify potential hazards, prevent injuries, and keep daily operations running smoothly in construction sites. With appropriate signage, you can create a safer environment and protect the lives of workers, supervisors, and visitors alike.

Need a sign for your construction site? Trust eSigns to get the job done. We offer a variety of aluminum signs, plastic signs, and other products that comply with OSHA standards.